Polycarbonate vs. ABS: Material Differences

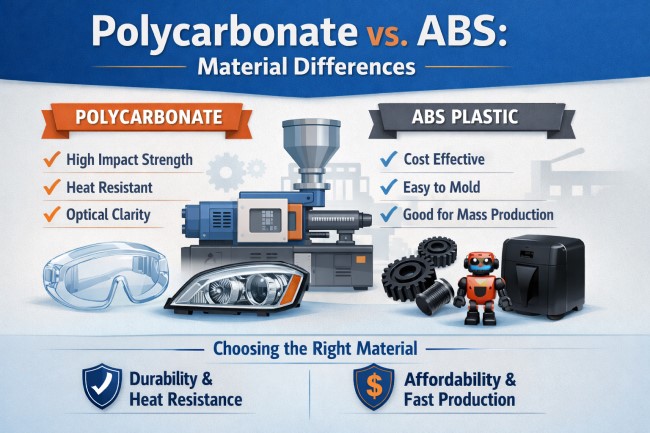

Choosing the right plastic matters in modern manufacturing. Engineers, designers, and product teams often compare Polycarbonate vs. ABS when strength, cost, and performance all play a role. Both materials are common in injection molding, yet they behave very differently in real-world use. Understanding these differences helps avoid costly mistakes and improves product quality.

Understanding Polycarbonate

Polycarbonate is known for its strength and clarity. It is a tough thermoplastic that can handle high impact without cracking. This makes it a popular choice for safety equipment, electronic housings, and automotive parts.

One key advantage of polycarbonate is heat resistance. It performs well in high-temperature environments where other plastics may deform. It also offers good dimensional stability, which is important for tight tolerances. Because of its transparency, polycarbonate is often used in products that require a clear or tinted finish.

However, polycarbonate comes at a higher cost. It can also scratch more easily unless treated with coatings. In precision manufacturing, tooling and process control must be handled with care to maintain surface quality.

Understanding ABS

ABS, or Acrylonitrile Butadiene Styrene, is widely used due to its balance of strength and affordability. It is lighter than polycarbonate and easier to process during molding. This makes ABS ideal for consumer products, toys, appliance housings, and enclosures.

When comparing Polycarbonate vs. ABS, ABS stands out for its ease of molding. It flows well in molds and supports high-volume production. Surface finishing is also simpler, which helps when parts need paint or texture.

ABS does have limits. It does not handle high heat as well as polycarbonate. Prolonged exposure to sunlight can also reduce its strength unless additives are used.

Polycarbonate vs. ABS in Manufacturing

The choice between Polycarbonate vs. ABS often depends on the application. If impact resistance and heat tolerance are critical, polycarbonate is the better option. If cost control and production speed matter more, ABS is often preferred.

In advanced production methods like Precision Unscrewing Plastic Injection Molding, material selection becomes even more important. Complex parts with threads or internal features require stable materials that release cleanly from molds. Both plastics can work, but polycarbonate offers better strength for threaded components, while ABS allows faster cycle times.

Manufacturers using Precision Unscrewing Plastic Injection Molding often evaluate both materials during prototyping. This ensures the final product meets performance goals without raising production costs.

To learn more about advanced molding solutions, you can explore this detailed guide on

Precision Unscrewing Plastic Injection Molding.

Cost, Durability, and Use Cases

Cost is a major factor in the Polycarbonate vs. ABS discussion. ABS is more budget-friendly and suitable for everyday products. Polycarbonate is an investment in durability and safety.

For electronics, ABS works well for internal components. For protective covers or load-bearing parts, polycarbonate offers better long-term reliability. In automotive and industrial settings, polycarbonate often outperforms ABS under stress.

Final Thoughts

There is no universal winner in the Polycarbonate vs. ABS comparison. Each material serves a clear purpose. The right choice depends on heat exposure, impact needs, design complexity, and production scale. By matching the material to the application, manufacturers can achieve better performance and longer product life.